African Skies Get a Breath of Fresh Air: EnviNOx® Technology Tackles Nitric Acid Plant Emissions

South African skies are about to breathe a sigh of relief. New legislation mandating lower Nitrogen Oxide (NOX) emissions from existing nitric acid plants has spurred a technological revolution, with thyssenkrupp Uhde's EnviNOx® process taking centre stage.

"This is a game-changer for African industry," declares Rajend Govender, CEO of thyssenkrupp Uhde South Africa, in a Sunday Times exclusive interview. "Factories can now meet stricter environmental standards while maintaining optimal production levels. It's a win-win for both the environment and the economy."

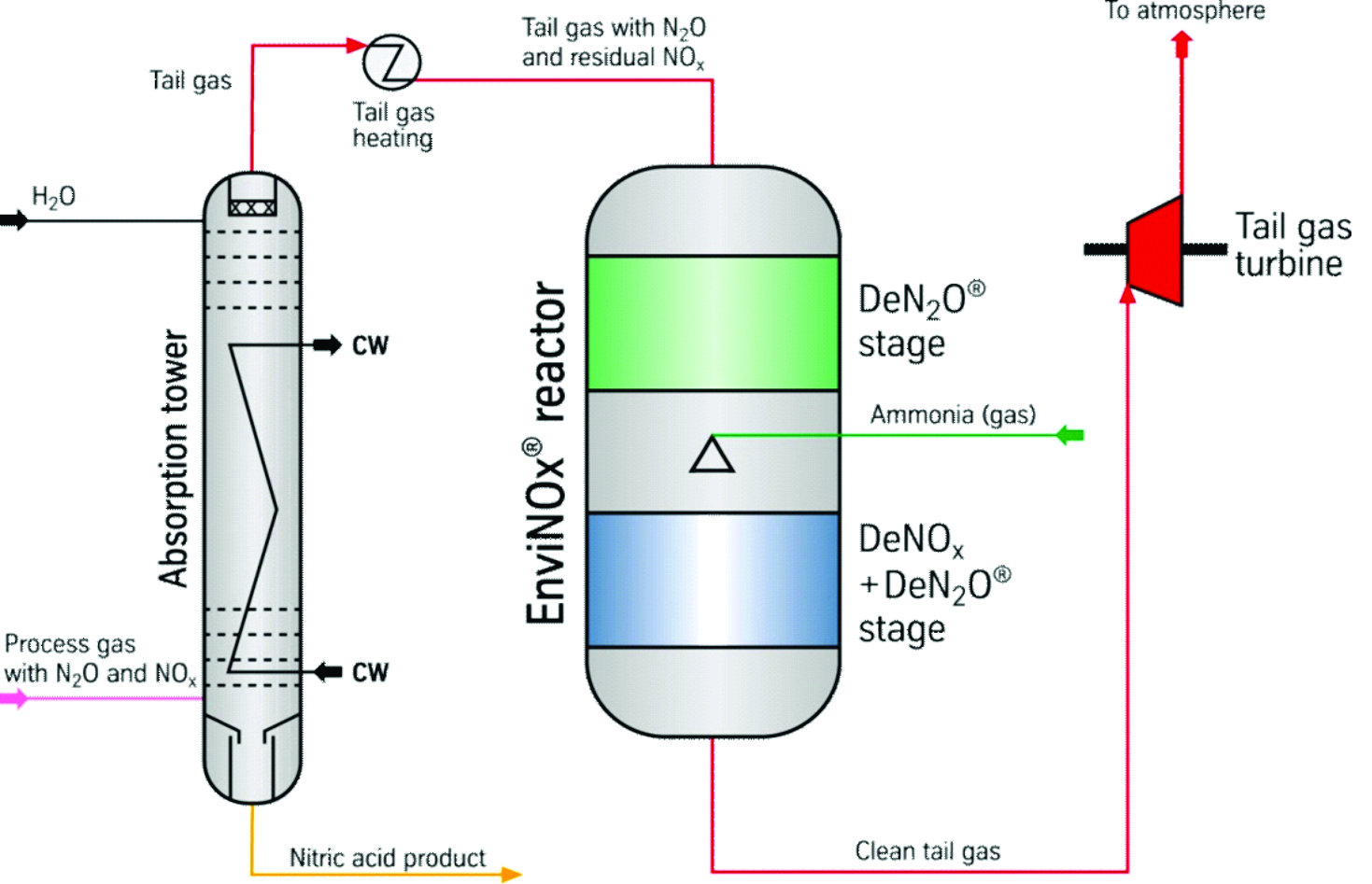

The villain in this story? NOX is a family of gases contributing to air pollution and ozone depletion. Nitric acid production, a cornerstone of fertilizer manufacturing, unfortunately, generates these harmful emissions. But EnviNOx® is the hero, boasting near-complete removal of NOX – and even the potent greenhouse gas N2O – transforming them into harmless nitrogen and water.

"Imagine a knight in shining armour for your factory's smokestack," says Nithesh Mohun, Business Development Manager at thyssenkrupp Uhde. "EnviNOx® boasts commercially proven performance, achieving near-zero NOX emissions and a staggering 99% reduction in N2O. It's a technological marvel with a profound impact on Africa's environmental future."

This innovation isn't just about cutting-edge science. It's about local expertise. EnviNOx® draws on the knowledge and partnership of thyssenkrupp Uhde, a company with a strong presence in South Africa. As the licensor for five out of six nitric acid plants in the country, they understand the unique challenges of the African industry.

The EnviNOx® story extends beyond borders. The technology has already seen success globally, with over 55 plants utilizing it worldwide. Africa, however, is taking a giant leap forward. Not only have four EnviNOx® systems been implemented in South Africa, but the continent also boasts the first EnviNOx® unit commissioned outside Europe – a testament to Africa's commitment to environmental progress.

But EnviNOx® offers more than just impressive numbers. Its modular design allows for flexibility. "We understand factories might not need N2O reduction today, but regulations might change tomorrow," explains Govender. "That's why EnviNOx® offers a future-proof solution. We can install a system ready for NOX reduction now, with the option to easily add N2O abatement later."

This adaptability is already making waves. thyssenkrupp Uhde recently secured a contract to retrofit their EnviNOx® technology at two South African nitric acid plants. "The initial focus was on NOX reduction," says Govender. "We provided an EnviNOx® ready solution, allowing for a smooth upgrade to N2O abatement when stricter South African regulations come into effect. It's a future-focused approach that benefits both the environment and our clients."

With EnviNOx® leading the charge, African skies are poised for a brighter, cleaner future. This technology signifies a powerful collaboration between international expertise and local knowledge, paving the way for a more sustainable future for African industry.